I’m working on a very nice mahogany English long case clock I’m dating as early 19th century, say 1815.

I find when hands working on something, vs just observing it as an antique, the connection with the mechanism makes one think about the hands that created; what was life like then, what was making things like then?

One thing we do know, the steel wasn’t the same!

Today’s steel production benefits from lots of technological developments over the past 200 years. I’ve seen this first hand, Metallurgy is advanced such that while the steel is being made samples are taken, analyzed and alloys added on the fly. We get consistent grades of steel with mill certificates of its chemistry and we know what chemistry will product what results.

Not so in 1815. Steel was a specialty product, almost a cottage industry until the invention of the Bessemer furnace around 1860.

And so?

This clock arrived with a badly damaged crutch rod. Broken and bent into a pretzel is more like it.

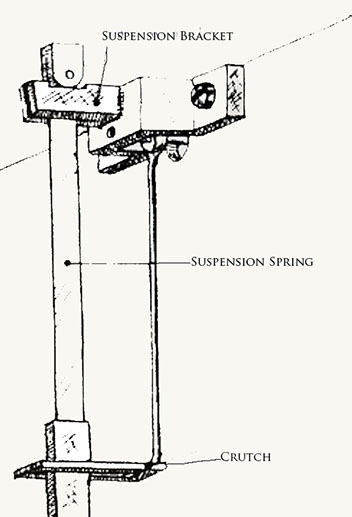

Not sure how that happened, but its suppose to look like below. The pendulum hangs on the spring and the crutch carries the pendulums motion to the escapement – what gives the tick tock

Whats interesting is how these old steels, perhaps blister steel or wrought iron, behaved when the pretzel bending occurred (how that happened is a mystery).

Its somewhat ductile in that much of it obviously bent….so its not like cast iron or wrought iron. However there is clear fracturing unlike what you’d expect with a modern steel at least the common ones I’ve used

The repair will be a silver soldered scarf joint. Just not sure how to get the 90 degree turn from horizontal to vertical just after the crutch.

Also, what I use should be fairly soft as you need to bend the rod (slightly) to set the clock in beat