the Versatility of the Alginment Tool

I know, its rather unbecoming to toot ones own horn, however when an idea works out this well I just have to tell someone!

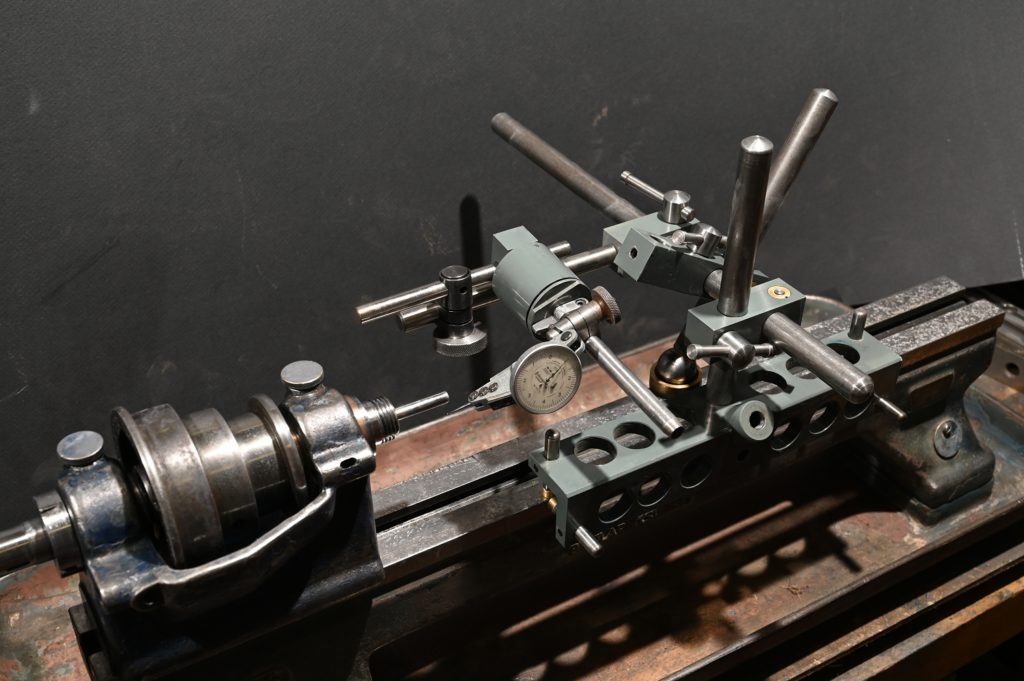

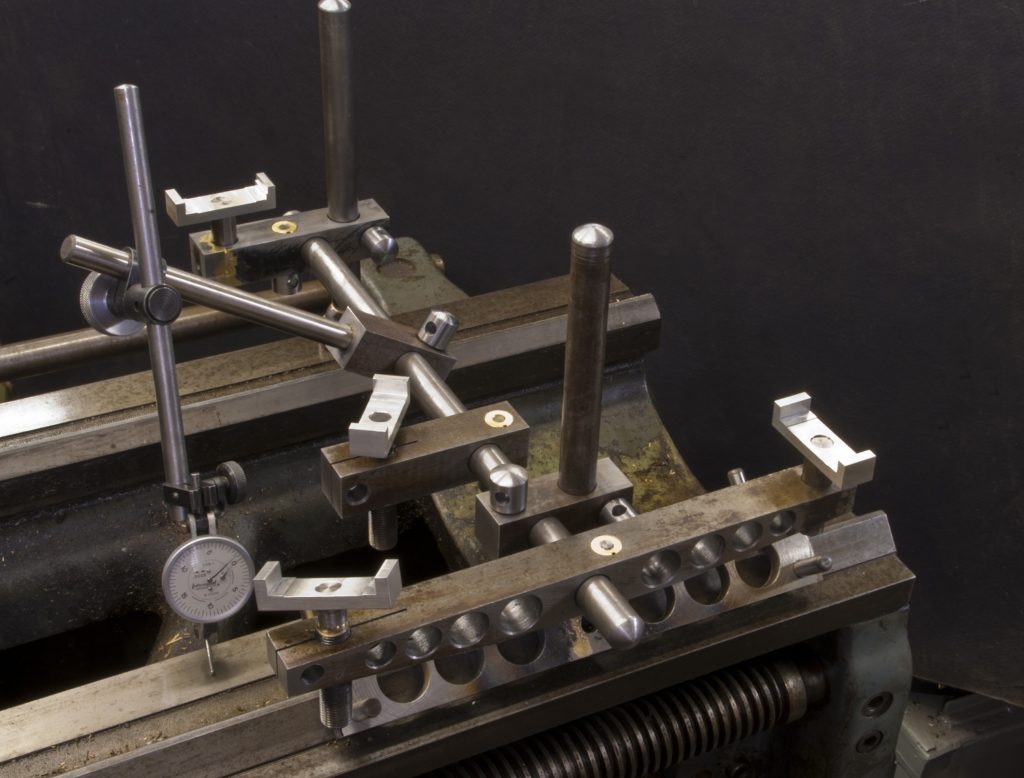

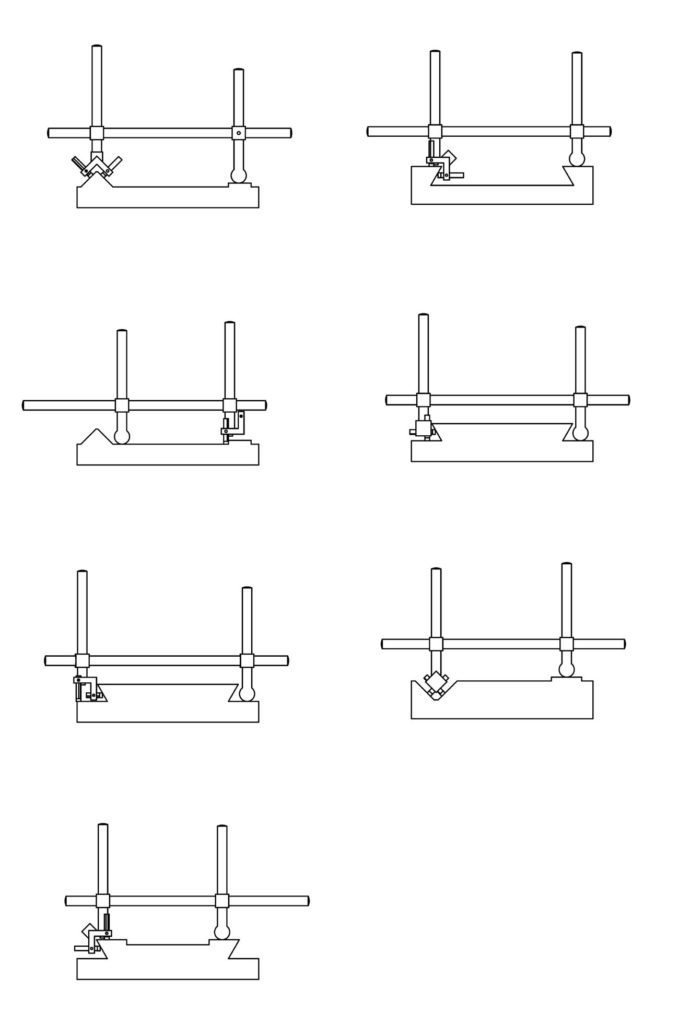

The main ‘foot’ of the alignment differs greatly from the Kingway Alignment tool. Its a 90 degree arrangement with two positions for the vertical post, 45 degrees apart. In one position its ideally suited to straddling a V way, in the other it handles box ways

The feet have brass pads so they don’t score the work. They are fixed by set screws and are adjustable in and out so that the foot can hand large and small machines

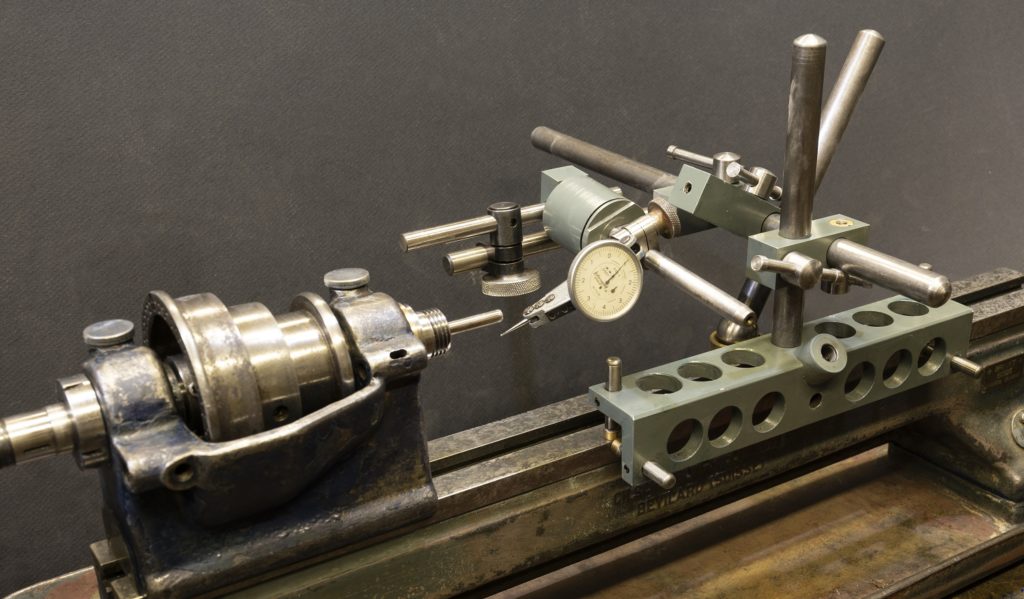

The claim of versatility as because the foot design accommodates all manner of ways, in all sizes. Here’s it working on a diminutive Schaublin 70, a small V way lathe and the large DSG lathe. With 5/8″ diameter bars, its robust even when extended to span large machine tool ways

The swing tool is another unique feature. You cannot drag an indicator along a cylindrical object, i.e. round bar, and expect to get accurate information about the bars relatioship along the plane you moved it it….because the bar could be missaligned in two planes

In other words, if chuck a ground bar in the lathe want see how compared to the Z axis (long direction of the lathe bed), you could not just crank the carriage up and and down the bed with an indicator on the round. It may be perfectly aligned in the horizontal plane, however if misaligned in the vertical plane, the indicator reading will be affecting my moving the diameter as it moves above or below the centre axis.

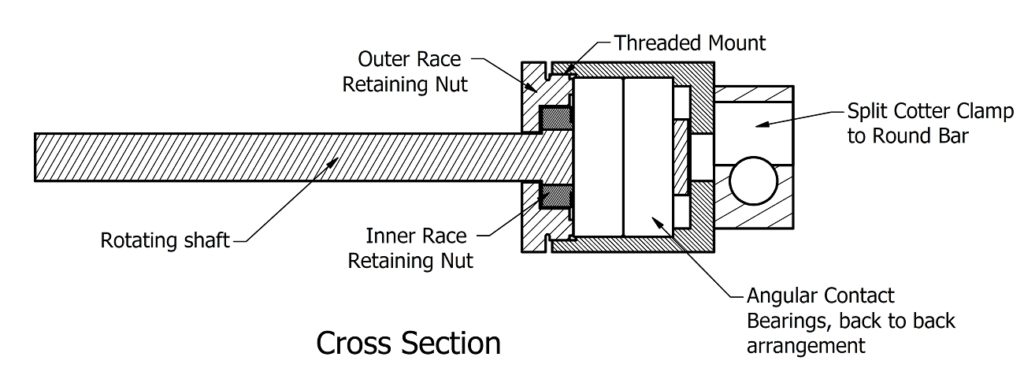

The only way to properly do this is with a sweep like – just like you would sweep an object on a surface plate. The sweep tool is essentially a small spindle lets you sweep an indicator point over an object, the move the alignment device along the bed and sweep and second point. comparing the two high points form the sweep provides reliable information on there relative positions in one plane