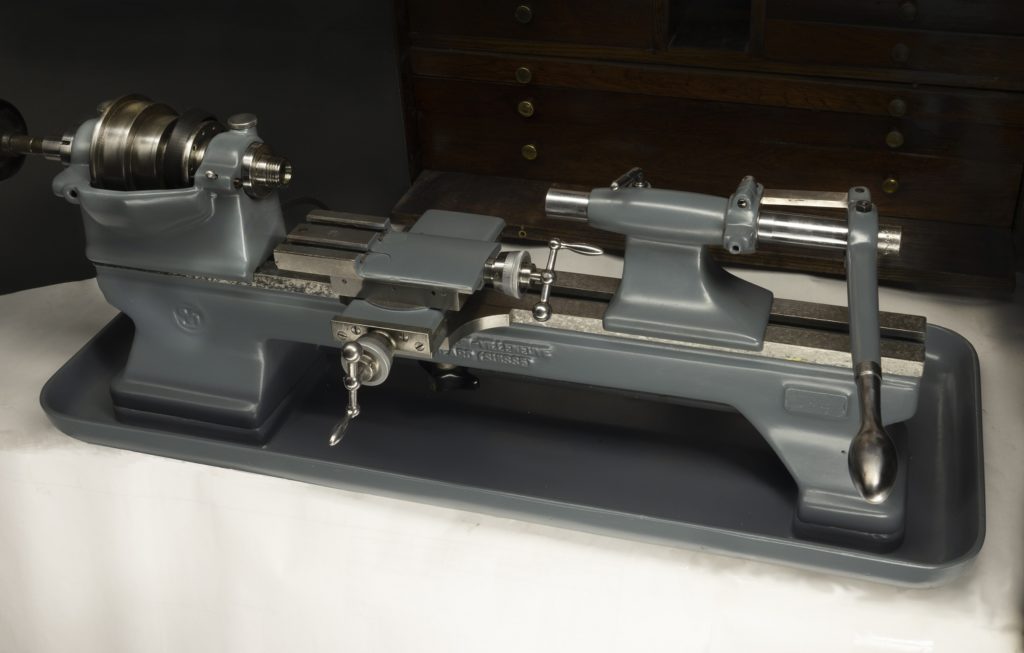

Reconditioning a Schaublin 70

Intro

With our North American approach to things, satisfying the masses is what drives most activity. In business, and in engineering, the expression “good enough, is, good enough” is quite correct. Making it better than it needs to be just increases costs and puts you at competitive disadvantage.

Then you own your first Swiss machine. A machine that comes from an environment where the mantra was (sadly most are gone now) make it as good as it can be.

That limited their target markets to small niches at the top of the pyramid, but what a joy they are to work on and use.

This is the story of a ground up recondition of Schaublin 70 to factory new condition, the most venerable instrument makers lathe of all time.

See below for details in each major component:

Precursor - About Scraping & Machine Tool Reconditioning

I’ve done a lot of scraping. Not as much as someone whose career has been reconditioning machines, but outside of that, likely more than most. I wrote a 12 part series on scraping that ran in Home Shop Machinist and am working on a follow up series “Reconditioning a Lathe”

What is it? Take something you know is very flat, say a Grade A surface plate. Smear over it a thin layer of Prussian blue (think oil paint that doesn’t dry) and touch a piece of work to the plate.

the “high” points on the work will have blue on them. You remove those areas with a hand scraper. Touch or “print” the work again and remove those. As the depth of cut (DOC) is limited to about 1/10,000 of an inch (a physical limitation of tool geometry and power you’re capable of applying), with enough iterations, the entire surface of the work will be to the same flatness as the surface, within the 1/10,000th of an inch DOC variance.

That’s a simplistic encapsulation of it, it gets more complicated as you are trying create not just flatness but specific and accurate relationships between geometries

Reconditioning